ALF

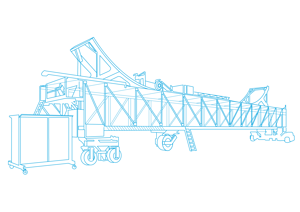

The Accelerated Loading Facility

The Accelerated Loading Facility (ALF) simulates heavy vehicle trafficking on pavement structures under controlled conditions. It allows valuable time and money to be saved in the evaluation of pavement performance compared to test sites carrying normal traffic.

The ALF allows pavements to be tested and for their performance to be evaluated in a very short timeframe compared with test sites under normal traffic.

A number of long-term pavement performance studies have verified ALF results against pavement performance under real traffic and environmental conditions.

ARRB first established the Australian ALF research program in 1984. The Australian ALF, currently based in Dandenong in Melbourne’s south-east, has operated continuously for more than 37 years, applying over 32 million load passes and simulating well over 300 million Equivalent Standard Axle loads.

What ALF Can be used for

- Rank relative performance of conventional and innovative materials or processes

- Investigate parameters used in pavement design

- Provide support for road construction activities such as full-scale proof testing

- Assist with development of network deterioration models including works effects

- Enhance full-scale long-term monitoring studies and life-cycle cost economic analysis

- Building capacity and expertise