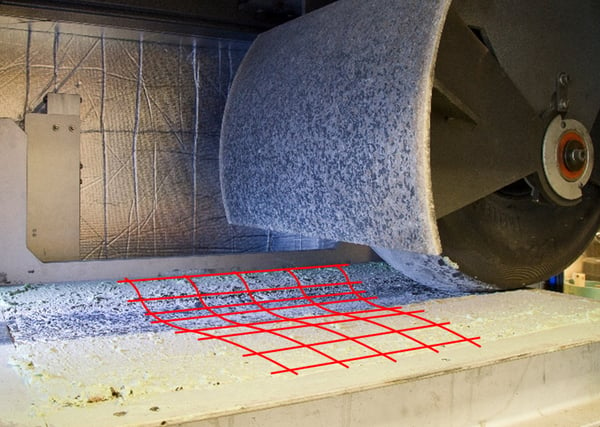

ARRB’s Austrack is a laboratory-based, extra-large wheel-tracking device which, building on its proven track record with virgin crushed rocks, is now being used to evaluate the performance of recycled materials.

By applying wheel loads comparable to heavy vehicles, the Austrack is able to predict the field rutting performance of unbound granular bases and subbase materials.

Recent work undertaken for the Department of Transport (DoT), Victoria has examined different combinations of recycled materials including recycled crushed concrete, crushed brick and crushed glass. While crushed concrete and crushed brick blends are commonly used in subbase layers in Victoria, DoT wanted to determine whether they could also be safely be used in road bases for some roads. DoT wanted an assessment of whether performance would be affected if a proportion of crushed glass, which can be often sourced locally, was incorporated into base materials?

ARRB used the Austrack to compare the performance of different blends of recycled crushed brick and crushed glass with a standard crushed concrete material, which was also tested as a control material. The different mixes performed well, and as a result DoT will extend the fit-for-purpose use of recycled material into unbound granular bases for lightly trafficked State roads. It is expected that the new DoT specification will encourage the use of more recycled aggregate in roads managed by local councils.

Austrack testing is a flexible and quick way to assess the rut resistance of new sources of recycled materials before their implementation. ARRB has built up a strong database of performance data which can be used to benchmark the engineering properties and performance of recycled materials.

For more information on Austrack testing, please contact Dr Didier Bodin or Shannon Malone.